In the first assessment of the Saw Kill’s micro-hydropower potential, one focal point was the Lower Saw Kill Dam as it historically was the site of a small hydroelectric power plant. The 2016 technical feasibility assessment of installing micro hydropower at the Lower Saw Kill Dam recommend utilizing aspects of that historic hydropower system but using state-of-the art technology to generate as much energy as possible while using only a fraction of the Saw Kill’s water. To learn more about the Saw Kill setting have a look at our previous posts.

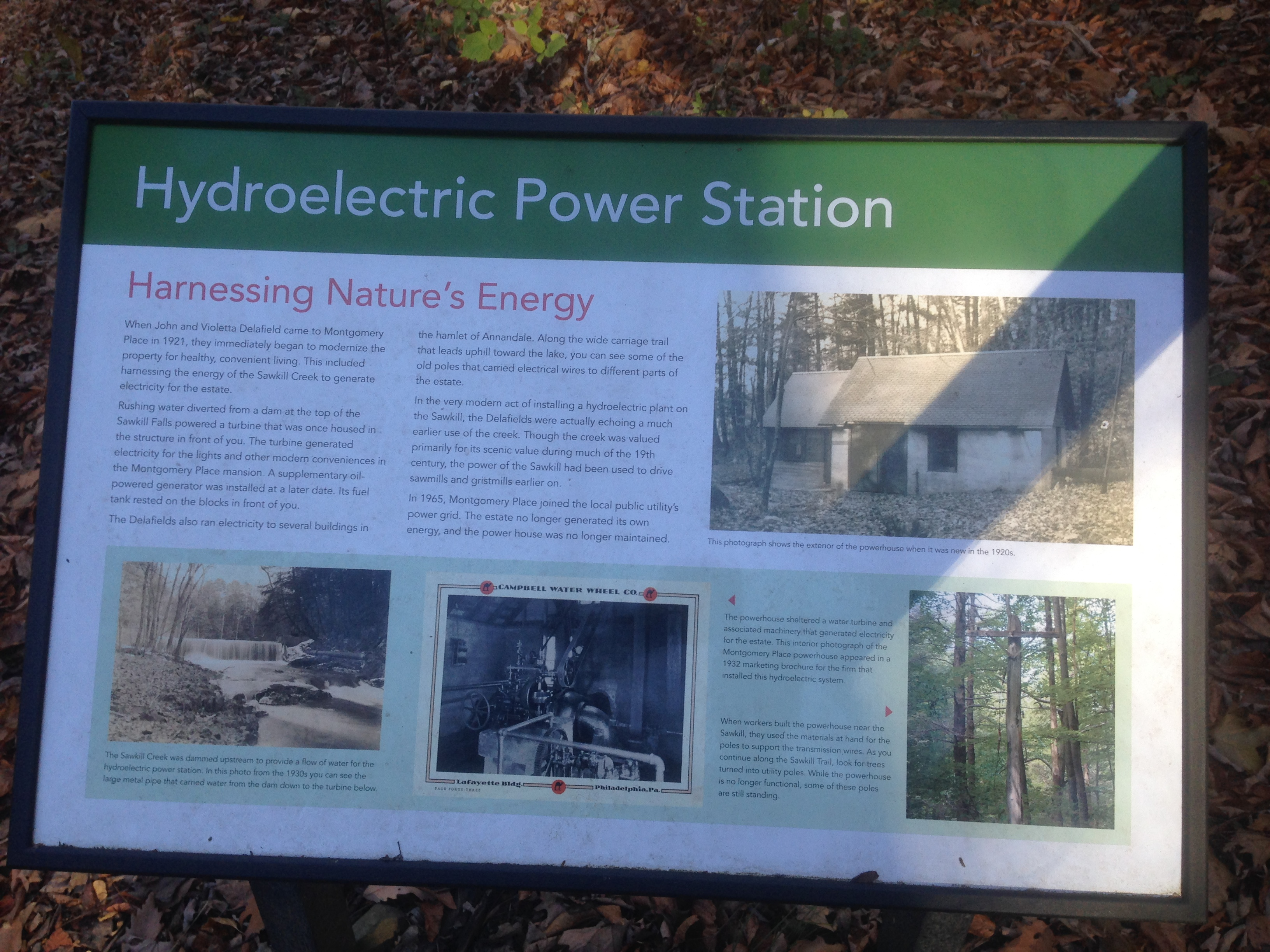

Remnants of the historic plant can still be found alongside the Saw Kill Trail from Montgomery Place: the old powerhouse and the steel penstock running up the dam.

Info signs along the Saw Kill Trail tell the history of the old hydropower plant.

The 2016 technical feasibility assessment of installing micro hydropower at the Lower Saw Kill Dam recommended utilizing the historic hydropower intake structure, replacing the penstock following its original path, and installing a modern micro hydropower turbine and generator at a location close to the historic end of the tailrace.

The use of light-weight HDPE piping, low-impact installation procedures, and high-end electronics promised a maximum generation capacity of 40kW using 15 cfs (0.425 m³/s) of flow (a fraction of the average 35 cfs that the Saw Kill carries). This design would have guaranteed a sufficient amount of water to flow through the bypass reach.

This relatively high power output is possible by using the maximum available elevation change between the height of the Lower Saw Kill Dam and the mouth of the Saw Kill, including the lowest waterfall. This system was designed for maximum efficiency and power output while minimizing the operating flow requirements and installation costs. The turbine-generator system proposed would have been located inside an underground vault, close to the stream edge, and minimizing the need for a draft tube.

There are reasons though, why this design was not the optimal solution. The upcoming post will talk more about those site-specific concerns as well as general concerns related to hydropower.

In an even earlier assessment to refurbish the old hydropower station, a former Bard student, Megan Kerins, focused her senior project, called “Micro Hydropower at Bard College: A Pre-Feasability Study” (April 2006), on the Lower Saw Kill Dam. The paper discusses three possible design schemes, ranging from 24 kW to up to 90 kW capacity, and looks at the historical, technical, environmental, legal, and economic aspects of the site. Have a look:

No responses yet